UV curing systems are revolutionizing auto shops by dramatically reducing repair times through swift drying and curing processes. Traditional methods taking hours or days are replaced by minutes, boosting efficiency, shop productivity, and customer satisfaction. These advanced systems utilize ultraviolet light to speed up chemical reactions in coatings, adhesives, and sealants, minimizing labor requirements and costs. As a result, UV curing systems have become an essential part of modern auto shops, ensuring faster turnaround times for various vehicle repair services.

In today’s fast-paced automotive industry, efficiency and quality are paramount. UV curing systems emerge as a game-changer, offering a revolutionary approach to drying and curing coatings on vehicles. This article explores why UV curing should be standard in auto shops. We delve into boosting efficiency by reducing downtime, enhancing quality through precision and consistency, and the significant environmental and cost advantages these systems provide. Discover how UV technology can transform your shop, ensuring long-lasting, high-quality finishes while minimizing waste and VOCs.

- Boosting Efficiency and Reducing Downtime

- – The impact of UV curing systems on speeding up drying and curing processes in auto shops

- – How UV technology minimizes wait times between application and vehicle release

Boosting Efficiency and Reducing Downtime

UV curing systems are a game-changer when it comes to boosting efficiency and reducing downtime in auto shops, particularly for car restoration and body shop services. Traditional drying methods can take hours or even days, leading to lengthy wait times for customers and reduced productivity for automotive repair services. UV curing dramatically cuts down this process by providing a quick and efficient alternative.

By using specialized UV lights, these systems cure paints, adhesives, and coatings in minutes instead of hours. This not only expedites the restoration process but also ensures consistent and high-quality results. Reduced downtime means faster turnaround times for automotive repair services, satisfying customers, and allowing shops to handle a higher volume of work without compromising on quality.

– The impact of UV curing systems on speeding up drying and curing processes in auto shops

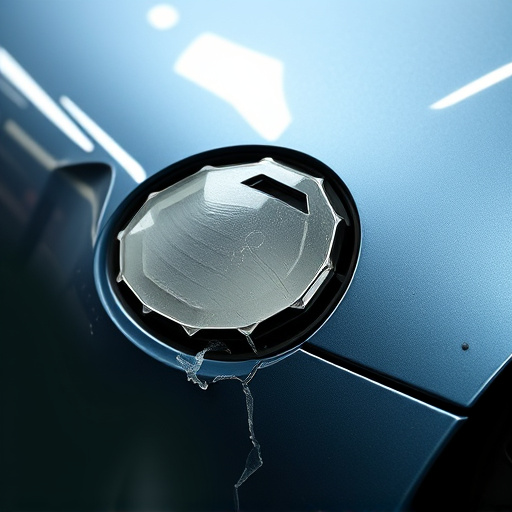

UV curing systems are transforming auto shops by significantly enhancing efficiency in drying and curing processes. These advanced technologies offer a swift alternative to traditional methods, reducing the time required for vehicle repair services, particularly in tasks such as fender repair and dent repair. By utilizing ultraviolet light to initiate chemical reactions, UV curing systems ensure that coatings, adhesives, and sealants set quickly, allowing auto shops to increase their throughput without compromising quality.

This speed is especially valuable in busy workshops where minimizing downtime for each vehicle is crucial. Moreover, the rapid curing process not only expedites service delivery but also contributes to cost savings by reducing labor requirements during the repair process. As a result, UV curing systems are becoming an indispensable component in modern auto shops, contributing to improved productivity and customer satisfaction across various vehicle repair services, including fender repair and dent repair.

– How UV technology minimizes wait times between application and vehicle release

UV curing systems offer a game-changing solution for auto shops, revolutionizing the way they handle automotive body work and car body repair. One of the most significant advantages is its ability to minimize wait times. Traditional drying methods often require hours or even days for paint or adhesives to set, but UV technology provides an efficient alternative. With UV curing, the application process speeds up dramatically, as the light rapidly hardens the materials used in dent repair and other body repairs. This means vehicles can be released much quicker, improving shop productivity and customer satisfaction.

By employing UV curing systems, auto shops can streamline their processes, reducing the time spent waiting for drying stages. This efficiency is especially beneficial for busy workshops dealing with numerous car body repair jobs daily. The rapid cure time ensures that vehicles are ready for the next stage of the repair process or collection much faster, contributing to a seamless and swift turnaround.

UV curing systems offer a clear path for auto shops to enhance efficiency, reduce downtime, and ultimately improve customer satisfaction. By speeding up drying and curing processes, these innovative technologies minimize wait times, allowing shops to serve more customers without sacrificing quality. Embracing UV curing systems is not just a step towards modernization; it’s a strategic move to stay competitive in today’s fast-paced automotive industry.